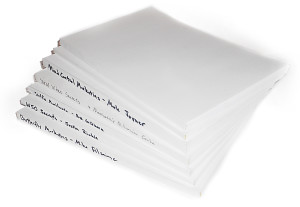

The first day I put my bookbinding jig into action I made 2 books – with covers – that were much better than any others I had made previously. The pages were all properly aligned, the spines were properly compressed for gluing, and the covers fit perfectly in one elegant step. The process took a fraction of the time wasted with my ‘sticks and clamps’ method.

As you are about to discover, building a simple bookbinding jig is both easy and fun. The jig will radically improve the speed and quality of the books you create.

As you are about to discover, building a simple bookbinding jig is both easy and fun. The jig will radically improve the speed and quality of the books you create.

Overview Of The Project

The purpose of a bookbinding jig is simple: line up the pages of your book quickly and easily (a process called ‘jogging’) and then hold the pages firmly in place as you glue the spine and apply the cover.

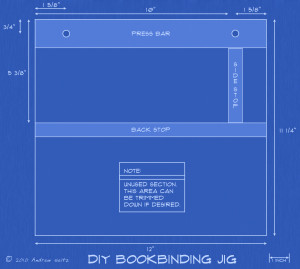

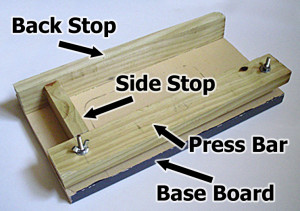

The main components of the bookbinding jig are the side stop, the back stop, and the press board. All three parts are secured to a sturdy base board which keeps everything properly lined up.

The main components of the bookbinding jig are the side stop, the back stop, and the press board. All three parts are secured to a sturdy base board which keeps everything properly lined up.

The press board rides on two bolts and is tightened with wing nuts while the side and back stops are permanently glued in place.

The design of the bookbinding jig uses pre-cut lumber as much as possible to minimize the cutting required. The machine cut edges from this lumber ensures that critical cuts are accurate. You will just have to trim boards to length.

Once the wood pieces are cut, you only need to do a little bit of gluing and drill 2 small holes.

If you can hang a shelf on the wall, you have all the skills required to build your own bookbinding jig.

So, take a deep breath and let’s get started.

Purchasing Supplies

Your shopping list for the bookbinding jig project breaks down into 4 major categories: hardware, wood, tools and glue. You may already have some or all of the tools required. If not, I recommend borrowing them from friends or family. Someone you know is likely to have most or all of them in the garage.

If you don’t have access to saws, you can usually get your local home improvement center to cut boards to length for little or no cost. Since the cuts don’t need to be super-precise, this is a perfect way to save a little cash on the project.

Dimensional Lumber – Wood

- 1”x2” Poplar

- 1”x12” Poplar

- 11/16”x11 1/4” Primed MDF (alternate for 1”x12” Poplar)

Hardware

- #10 Stainless Steel Flat Washers

- #10 – 24 x 3” Flat Head Bolts

- #10 – 24 Wing Nuts

- #10 – 24 Lock Nuts

Tools

- 7/64” Drill Bit

- Countersink Drill Bit

- Wood Clamps

- Screw Driver

- Miter Saw or Finish Cut Saw

- Pencil

Glue

- Liquid Nails Construction Adhesive

The backstop and side stop are both glued into place. There are many types of glue on the market that will work perfectly well for this project. But, I use and recommend small project construction adhesives like Liquid Nails for strength and ease of use. It dries fast and will provide a nice durable bond.

The hardware required is simple as well (hey, simplicity is my goal!) Two bolts, 2 nuts, 2 wing nuts, and a couple washers.

Special Note on Dimensional Lumber

Working with wood can get a little confusing. The 1” x 2” piece of finished wood that you purchase at the home improvement center is actually 3/4” x 1 1/2” in size.

The 1” x 2” measurement refers to the size of the board when it was first cut. But wood gets dried and planed after the initial cut and that reduces the final product down to the 3/4” x 1 1/2” finished size.

The designs and measurements for the DIY Bookbinding Jig take this into account.

Measuring and Cutting

There are 4 pieces of lumber to be cut for the bookbinding jig: the base board, the side stop, the back stop, and the press bar.

The dimensions included here are designed to create a jig used for binding 5 1/2” x 8 1/2” paperback books. To create books of other sizes you can scale the dimensions as needed.

The dimensions included here are designed to create a jig used for binding 5 1/2” x 8 1/2” paperback books. To create books of other sizes you can scale the dimensions as needed.

Using this basic design, you can build a jig for books up to 10 1/2” wide using the lumber list included. Just adjust the locations of the side and back stops to fit your page size.

Since the lumber list is based on common dimensional sizes, the only cuts you are required to make are for length.

Most home centers and smaller lumber yards will cut lumber for you. Even if you have the tools for cutting, this is a huge time and mess saving option. I recommend you let them do the cutting for you.

My local home center has a cut-it-yourself miter saw in the molding section of the lumber area. This is perfect for cutting the wood for the side stop, back stop, and press boards.

Here is the list of cut pieces required:

- 2 – Press Bar and Back Stop: 1” x 2” x 12”

- 1 – Side Stop: 1” x 2” x 3 3/4”

- 1 – Base Board: 1” x 12” x 12”

Once the boards are cut to length, the next step is to mark the locations for the side stop and back stop on the base board.

Now, this drawing for the jig looks very precise and professional, but my personal measuring technique is actually pretty low tech.

I start by lining up the press bar along the edge of the baseboard. With a sharp pencil, I draw a line on the baseboard along the inside edge of the press board. Then, I set the press board aside.

The finished book dimensions that we will be creating with this jig are 5 1/2” x 8 1/2”. These are the dimensions of a standard US letter-sized page (8 1/2” x 11”) folded in half. So, my next super complex step is to fold a letter-sized sheet of paper in half.

I take the folded sheet of paper and place it on the base board. I center the paper top and bottom and hang the left edge about 1/8” past the end of the base board.

Hold the paper firmly in place and use your pencil to trace the top and right edges onto the base board.

The super-precision measuring is now complete!

Gluing and Drilling

Once your lumber is cut and you’ve drawn your alignment marks on the base board, it is finally time to put everything together.

Step One

Take the side stop and apply a thin layer of glue to the bottom edge. Carefully position it so that the edge of the stop lines up with the guide mark you drew on the base board. Also make sure that the end of the side stop does not overlap the area where the press board will go. It is best to leave a small gap on that end so that there is a little ‘wiggle room’ (in case your measurements were not exactly ‘super-perfect’.)

Holding the side stop in place, use the clamp to press it firmly in place and allow it the glue to dry. If any glue squeezes out along the inside edge after you apply the clamp, wipe it up quickly so you leave a nice clean edge for your book pages to line up against.

When the glue has dried for the side stop, repeat the process and glue down the back stop lining it up with the marks you made on the base board.

Step Two

The second and final step is to drill the holes for the threaded bolts that the press bar will ride on. Place the press bar in place and clamp it down securely. Then, mark the centers for each of the bolt holes.

Using the 7/64” drill bit, drill 2 holes all the way through the press bar and the base board below it. Place a piece of scrap wood under the base board as you drill your holes to prevent splintering as the bit exits the back of the wood.

Swap the drill bit for a counter-sink bit. Remove the clamp and the press bar and set them aside. Then, use the countersink bit to widen the top of the holes on the base board.

Place a washer on one of the bolts and thread it through the bottom of the base board. Then, place a nut on the bolt from the other side and tighten it down until the nut settles into the depression created with the counter-sink bit. Tighten it snug and repeat on the other side.

When both bolts are securely in place on the base board, place the press bar over the bolts and slide it into place. The fit might be a bit snug. If so, adjust the bolts until everything slides easily. Then, place a washer and a wing nut on each bolt.

Your Bookbinding Jig is now ready for use!